Smart Recovery of Wood Chips

As we always say, sustainability is an integral part of our corporate philosophy. That’s why every stage of our wooden tool handle production is designed to minimize waste and make the most of available resources.

At Foppoli Bramin, we take a targeted approach to waste reduction, not only to optimize production processes but also to actively contribute to a circular economy model.

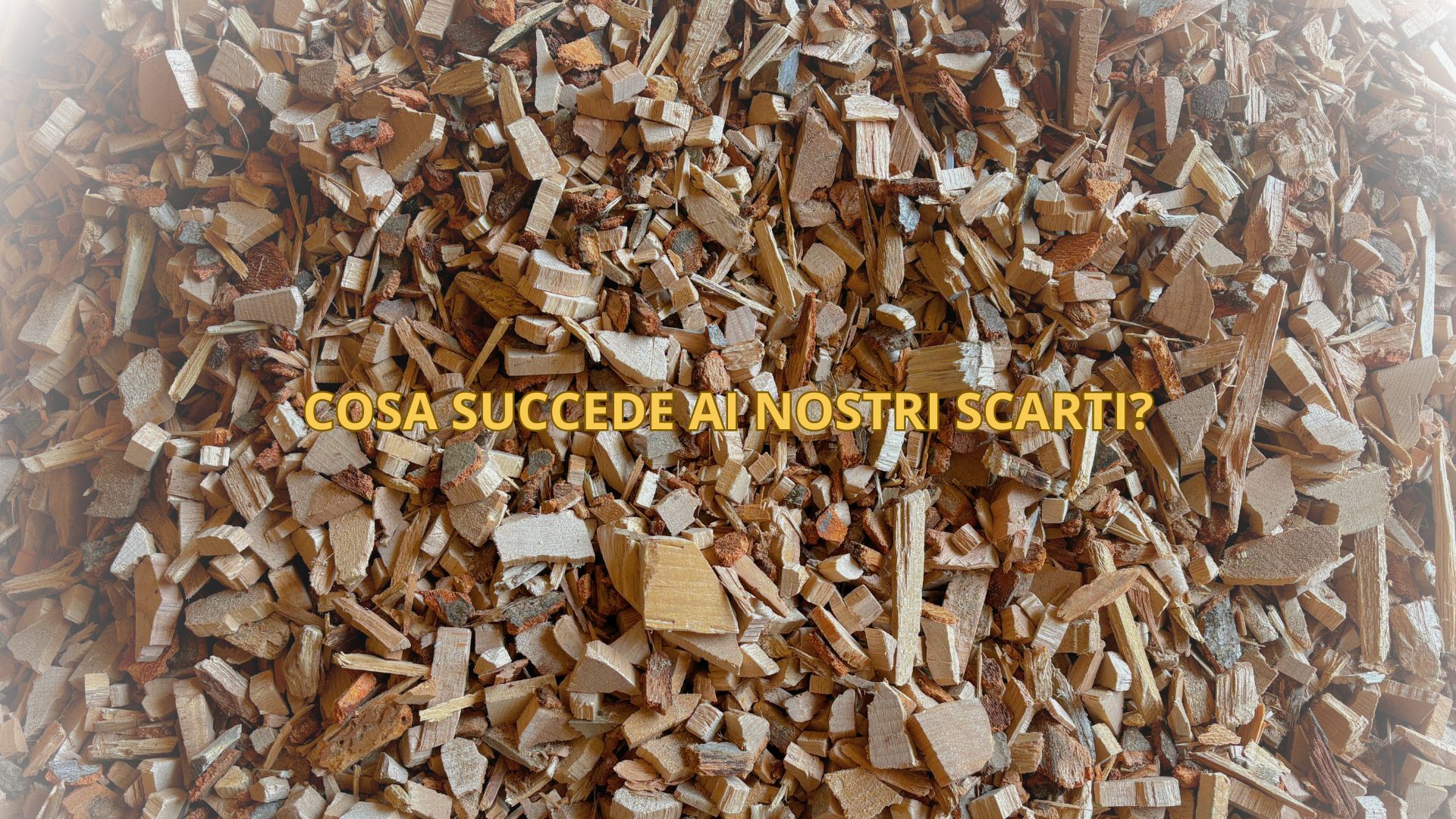

One of the most effective practices is the recovery of wood processing waste, which we transform into wood chips—a versatile and sustainable raw material. This allows us to give new life to materials that would otherwise be discarded, ensuring a more efficient use of natural resources. Thanks to this strategy, we create a balance between productivity, efficiency, and environmental responsibility, benefiting both our company and the region where we operate—an aspect we deeply care about.

A Virtuous Cycle: Wood Chips as a Resource

How does wood chip recovery work? During the processing of our wooden tool handles, a portion of the material is discarded as shavings and residues. Instead of being thrown away, these scraps are collected, sorted, and processed into wood chips. The selection process is carefully managed to ensure the material is free of impurities and ready for efficient reuse.

Since our wood chips come from untreated wood, they are completely reusable. They can be used not only as an eco-friendly fuel but also in various industrial sectors that require raw wood. This approach helps us reduce waste and repurpose every leftover material, ensuring nothing goes to waste unnecessarily.

From Heating to Pellet Production

The use of wood chips follows two main paths:

- Heating our facilities: A portion of the wood chips is used to fuel the heating system of our production plants, reducing dependence on external energy sources and lowering our environmental impact.

- Supply to pellet manufacturers: The remaining wood chips are sold to specialized partners who use them as raw materials for pellet production. This process ensures an efficient and circular use of wood, contributing to waste reduction and promoting eco-friendly heating solutions.

A Concrete Commitment to Sustainability

The recovery of wood chips is a tangible example of our commitment to a more responsible production model. To summarize, this business decision allows us to:

- Minimize production waste.

- Optimize the use of natural resources.

- Promote a circular economy that maximizes the value of every part of the wood.

Reusing scraps from wooden tool handles is a smart way to improve our operations and reduce environmental impact. Every day, we seek new solutions to repurpose every part of the wood, avoiding unnecessary waste. What was once considered waste can now become energy, heat, or a new raw material for further processing.

Small choices like this, in our opinion, make a real difference in creating a more sustainable industry!